Conductive PTFE hose Manufacturer, Factory, Supplier In China

With about 20 years of experience since 2005, we are one of the leading manufacturer of conductive PTFE hoses in China. Our advanced technology and dedicated professional team ensure top-quality products that meet stringent industry standards. Trust us for reliable, high-performance conductive polytetrafluoroethylene hoses designed to deliver exceptional durability and efficiency.

Accepting OEM, ODM, SKD orders, we have rich experiences in production and research development for different PTFE hose types.

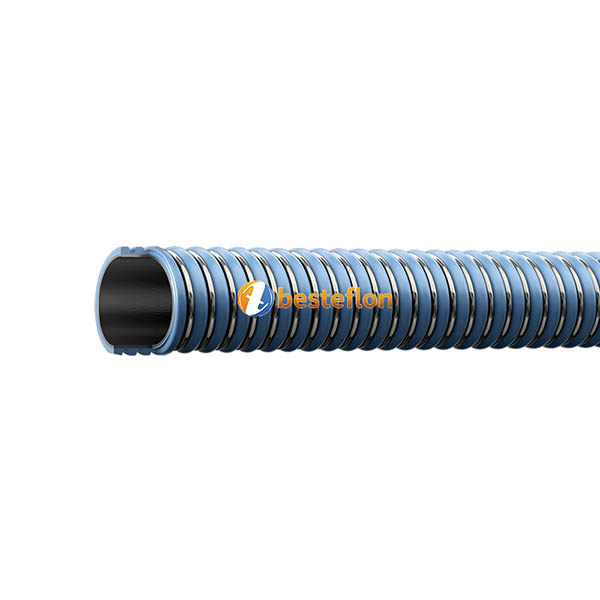

Conductive PTFE Hoses

Different with nonconductive version, conductive PTFE hoses are those that have a conductive resin liner made of carbon black, which imparts conductivity to the PTFE material and allows them to conduct electricity.

Like the conductive PTFE fuel hose, the conductive lining provides a path for static electricity to dissipate from the hose, preventing the buildup of static charge. The buildup of static charge can be dangerous in certain applications where a spark could ignite the fuel and cause an explosion, which makes the conductive liner ideal for use in PTFE fuel line running gas, E85, methanol, etc.

The carbon black liner is applied to the PTFE tube during the manufacturing process, ensuring uniform conductivity throughout the length of the hose.

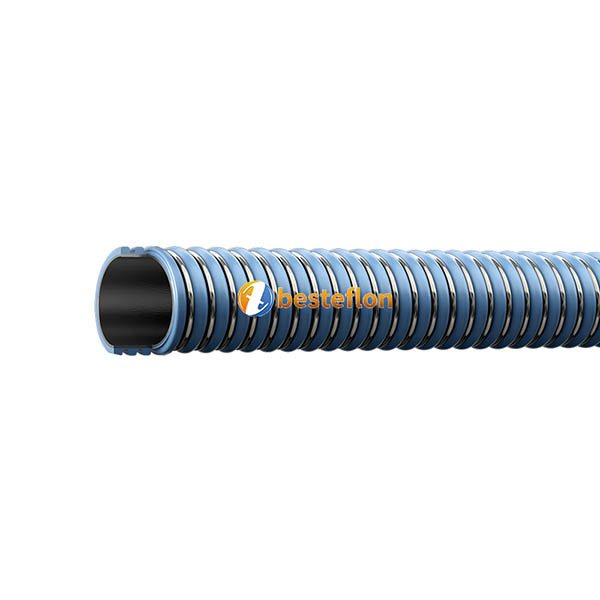

Conductive PTFE tube

Material: Carbon Black Layer + PTFE Tube

Type: Smooth Bore tube and Convoluted tube

Tube wall thickness: 0.85mm - 1.5mm (depending on sizes)

Temperature range: -65℃ ~ +260℃ (-85℉ ~ + 500℉), noted: higher temperature, lower pressure

Properties:

Low expansion coefficient

High temperature and high pressure resistance

Compatible with almost all of the fuel

All assembly tubes have been strictly pressure-tested

Non-stick, smooth surface, low coefficient of friction

Resistance to weathering and aging performance

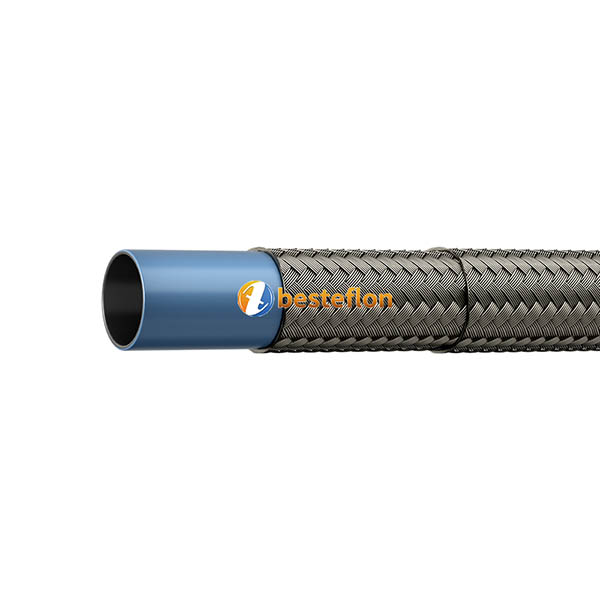

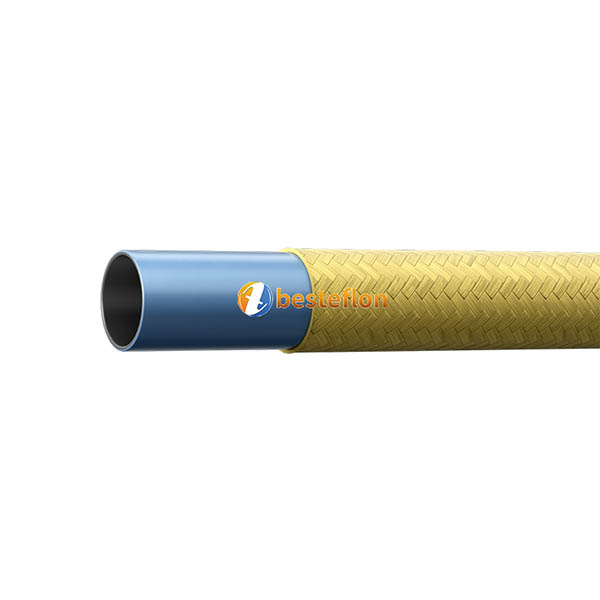

Anti-static PTFE Smooth Bore Hose

Inner tube: Carbon Black Layer + PTFE Tube

Tube wall thickness: 0.7mm - 2mm (depending on sizes)

Reinforcement/Outer layer: Single layer high tensile stainless steel 304/316 wire braided, double layered SS braided version, and outer cover can be polyester, aramid fiber, glass fiber, PVC, PU, nylon, silicone, etc.

Temperature range: -65℃ ~ +260℃ (-85℉ ~ + 500℉), higher temperature, lower pressure

Properties:

Low expansion coefficient

High temperature and high pressure resistance

Compatible with almost all of the fuel

All assembly tubes have been strictly pressure-tested

Non-stick, smooth surface, low coefficient of friction

Resistance to weathering and aging performance

Applications:

Brake system, Fuel system, Hydraulic system (clutch, transmission, power steering, etc.), All air and gas applications,Instrument, and sensor lines, chemical, pharamceutical & food processing, plastic & rubber molding machines. Also for some applications the tube can also be made conductive to dissipate electro-static charges.

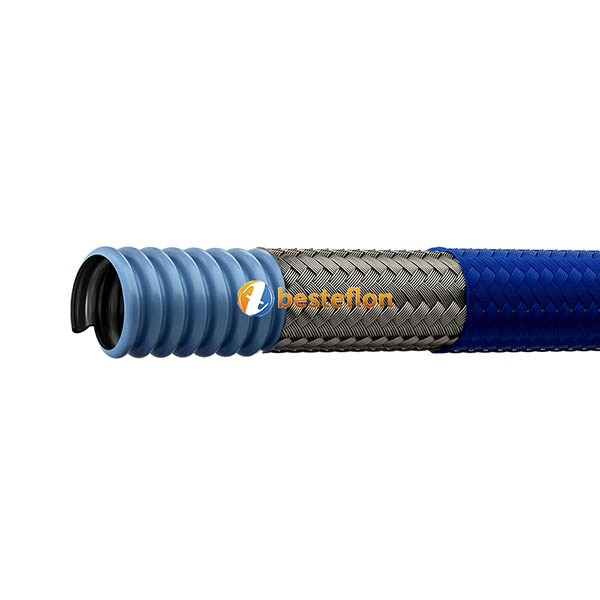

Anti-static PTFE Convoluted Hose

Inner tube: Carbon Black Layer + PTFE Tube

Tube wall thickness: 0.65mm - 2mm (depending on sizes)

Reinforcement/Outer layer: Single layer high tensile stainless steel 304/316 wire braided, double layered SS braided version, and outer cover can be polyester, aramid fiber, glass fiber, PVC, PU, nylon, silicone, etc.

Temperature range: -65℃ ~ +260℃ (-85℉ ~ + 500℉), noted: higher temperature, lower pressure

Properties:

Low expansion coefficient

High temperature and high pressure resistance

Compatible with almost all of the fuel

All assembly tubes have been strictly pressure-tested

Non-stick, smooth surface, low coefficient of friction

Resistance to weathering and aging performance

Applications:

Brake system, Fuel system, Hydraulic system (clutch, transmission, power steering, etc.), All air and gas applications, chemical, pharamceutical & food processing, plastic & rubber molding machines. Also for some applications the tube can also be made conductive to dissipate electro-static charges.

Customization Options

As a manufacturer of conductive PTFE hoses, our company offers the following customization options:

Features/Advantages

1. Superior Conductivity: Our conductive PTFE hoses are engineered with carbon black layer applied to PTFE tube, ensuring exceptional electrical conductivity. This feature is crucial for applications where static buildup can pose a risk, providing a safe and reliable solution for the transfer of volatile or flammable substances.

2. High Chemical Resistance: The PTFE material used in our hoses offers outstanding resistance to a wide range of chemicals, including acids, solvents, and corrosive substances. This makes our anti-static PTFE hose ideal for use in harsh industrial environments where other materials might degrade.

3. Exceptional Durability: Designed to withstand extreme temperatures and pressures, our conductive PTFE hoses maintain their integrity under the most demanding conditions. This durability ensures long service life and reduced maintenance costs, making them a cost-effective choice for heavy-duty applications.

4. Flexibility and Versatility: Our hoses combine the flexibility of PTFE with the added benefit of conductivity, allowing for easy installation in complex systems and tight spaces. They are suitable for a variety of industries, including chemical processing, pharmaceuticals, and food and beverage, etc., providing a versatile solution for a wide range of applications.

Don’t you find what you are looking for?

Just tell us your detailed requirements. The best offer will be provided.

Conductive PTFE Hose Manufacturing Process

Authentication Certificate

FDA

IATF16949

ISO

SGS

FAQS

A conductive PTFE (Polytetrafluoroethylene) hose is a type of flexible hose designed to handle high-pressure applications while dissipating static electricity. The hose is made from PTFE, a synthetic fluoropolymer, and includes a conductive carbon layer or other conductive materials to prevent static buildup. This feature is crucial in applications involving flammable or volatile substances, as it reduces the risk of ignition from static sparks. The hose's smooth interior ensures efficient fluid flow, and its flexibility allows for easy installation in tight spaces.

Conductive PTFE hoses are used in various industries due to their durability and resistance to chemicals, high temperatures, and pressure. Primary applications include:

· Chemical processing and transfer

· Pharmaceutical production

· Food and beverage processing

· Fuel and oil transfer

· Hydraulic systems

· Aerospace and automotive industries These hoses are ideal for transporting aggressive chemicals, solvents, and other hazardous materials safely.

The key benefits of using a conductive PTFE-lined hose over a non-conductive hose include:

· Static Dissipation: Prevents static buildup, reducing the risk of ignition in flammable or volatile environments.

· Chemical Resistance: Withstands aggressive chemicals and solvents without degrading.

· Temperature Resistance: Operates effectively in a wide temperature range, from -65°F to 450°F (-54°C to 232°C).

· Flexibility and Durability: Offers excellent flexibility for easy installation and long-term durability in demanding conditions.

· Smooth Inner Surface: Ensures efficient fluid flow with minimal pressure drop and resistance.

Choosing the right conductive PTFE hose involves considering several factors:

· Chemical Compatibility: Ensure the hose material is compatible with the substances being transported.

· Temperature Range: Select a hose that can withstand the operating temperature of your application.

· Pressure Rating: Verify that the hose can handle the maximum pressure of your system.

· Size and Length: Choose the appropriate diameter and length to meet your system's requirements.

· Fitting Compatibility: Ensure the hose fittings match your equipment connections.

· Compliance: Check for industry-specific certifications and standards that the hose must meet, such as FDA compliance for food and beverage applications.

Maintaining conductive PTFE hoses involves regular inspections and proper handling:

· Regular Inspections: Check for signs of wear, damage, or degradation, especially at the fittings and along the hose length.

· Proper Storage: Store hoses in a cool, dry place away from direct sunlight and harsh chemicals.

· Cleaning: Clean the hoses according to the manufacturer's recommendations to prevent contamination and buildup.

· Handling: Avoid excessive bending, kinking, or twisting during installation and use to prevent damage.

· Replacement: Replace hoses at the first sign of significant wear or damage to maintain safety and performance.

Yes, conductive PTFE hoses must meet various industry standards and certifications, depending on their application. Key standards and certifications include:

· FDA: Compliance for food and beverage applications to ensure safety and hygiene.

· ISO: Various ISO standards for quality and performance, such as ISO 9001.

· SAE: Standards from the Society of Automotive Engineers for automotive and aerospace applications.

· RoHS, SGS, IATF 16949, etc.

Meeting these standards ensures that the hoses are safe, reliable, and suitable for their intended applications.

.jpg)