Smoothbore Heavy Wall PTFE Hose – China Manufacturer | BESTEFLON

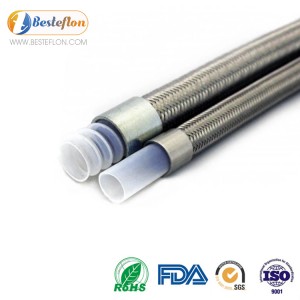

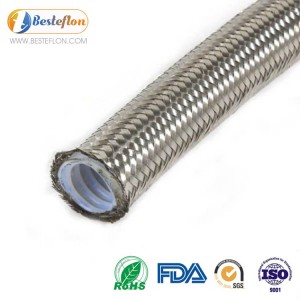

Heavy wall PTFE Smoothbore hose is made of thickened PTFE inner tube, and the outer layer is braided with hard 304 SS wire,which can well protect the inner tube from damage.

As the thickness of the tube wall increases, the tube strength and rupture pressure also increase. Compared with standard tubes, Heavy wall PTFE Smoothbore hoses are more resistant to high temperature and high pressure, and will have better air tightness. These hoses are mainly used in long-term high temperature and high pressure working environment. The available sizes are from 1/8" to 4", and this highly durable PTFE hose can be used to address your demanding transmission challenges to liquids such as acids, solvents, fuels, adhesives, hydraulic oils, thermal oils, and various types of chemicals. It is ideal for almost all demanding high-purity and chemical applications.

Features of the Heavy wall PTFE Smoothbore hose:

1. Resistance to kink:Thicker PTFE tubes are more resistant to gas penetration than standard ones, increasing hardness and heat resistance to cycling and kink and excessive bending.

2. Resistant to corrosion - PTFE is inert and tolerant to most chemicals and reagents, and has zero corrosion rates and low life-cycle costs.

3. Easy to clean - Non-stick, bacteria do not gather and survive, and can be cleaned with steam, cleaner, corrosive agent or solvent.

4. Hygienic - FDA-approved materials meet or exceed Pharmacopeia Class VI and 3A standards. Does not contaminate or impart taste, color or odor to any medium.

5. Durable - Designed for extended use in harsh environments involving severe chemical, thermal and mechanical stresses. Even under extreme thermal cycles, it does not suffer from aging or embrittlement like other plastic products.

6. Anti-static - conductive carbon can be added to the tube to export the static electricity generated in operation to avoid explosion.

Product Details

| Brand Name: |

BESTEFLON |

| Material: | 100% virgin PTFE |

| Specification: | 1/4'' to 1'' |

| Thickness: | 0.65/1/1.2/1.5/2MM |

| Inside hose color: | milky white/translucent |

| Temperature range: | -65℃--+260℃ |

| Wire braided: | 304/316 stainless steel wire braided |

| Appliecation: | Chemical/Machinery equipment//Compressed gas/Fuel and lubricant handling/Steam transfer/Hydraulic systems/Food industry/Tire industry/shipbuilding/pharmaceutical industry |

Convoluted Hose Range

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXBW201-04 | 3/16" | 5.0 | 0.433 | 11.0 | 0.035 | 0.90 | 2944 | 203 | 8831 | 609 | 0.709 | 18 | -3 | ZX710-03 |

| ZXBW201-05 | 1/4" | 6.5 | 0.472 | 12.0 | 0.035 | 0.90 | 2489 | 172 | 7468 | 515 | 0.787 | 20 | -4 | ZX710-04 |

| ZXBW1201-06 | 5/16" | 8.0 | 0.516 | 13.1 | 0.035 | 0.90 | 2001 | 138 | 6003 | 414 | 0.906 | 23 | -5 | ZX710-05 |

| ZXBW201-08 | 3/8" | 10.0 | 0.610 | 15.5 | 0.035 | 0.90 | 1730 | 119 | 5191 | 358 | 0.984 | 25 | -6 | ZX710-06 |

| ZXBW201-10 | 1/2" | 13.0 | 0.756 | 19.2 | 0.035 | 0.90 | 1498 | 103 | 4495 | 310 | 1.102 | 28 | -8 | ZX710-08 |

| ZXBW201-12 | 5/8" | 16.0 | 0.906 | 23.0 | 0.035 | 0.90 | 1160 | 80 | 3480 | 240 | 1.969 | 50 | -10 | ZX710-10 |

| ZXBW201-14 | 3/4" | 19.0 | 1.055 | 26.8 | 0.035 | 0.90 | 1015 | 70 | 3045 | 210 | 2.480 | 63 | -12 | ZX710-12 |

| ZXBW201-16 | 7/8" | 22.2 | 1.181 | 30.0 | 0.039 | 1.00 | 923 | 64 | 2770 | 191 | 3.346 | 85 | -12 | ZX710-14 |

| ZXBW201-18 | 1" | 25.0 | 1.299 | 33.0 | 0.039 | 1.00 | 793 | 55 | 2378 | 164 | 3.543 | 90 | -16 | ZX710-16 |

| ZXBW201-20 | 1-1/8" | 28.0 | 1.398 | 35.5 | 0.039 | 1.00 | 575 | 40 | 1726 | 119 | 3.740 | 95 | -18 | ZX710-18 |

| ZXBW201-22 | 1-1/4" | 32.0 | 1.634 | 41.5 | 0.055 | 1.40 | 450 | 31 | 1349 | 93 | 3.937 | 100 | -20 | ZX710-20 |

| ZXBW201-26 | 1-1/2" | 38.0 | 1.890 | 48.0 | 0.059 | 1.50 | 392 | 27 | 1175 | 81 | 6.102 | 155 | -24 | ZX710-24 |

| ZXBW201-32 | 2" | 50.0 | 2.461 | 62.5 | 0.079 | 2.00 | 300 | 21 | 899 | 62 | 7.874 | 200 | -32 | ZX710-32 |

* Customer-specific products may be discussed with us for detailed.

Production Workshop

Read more news

HOW TO CUT PTFE HOSE

PTFE tube is generally treated by a cutting machine. Cutting machine cutting PTFE Tube can effectively prevent tube deformation. There is nothing more painful than stabbing a finger with the worn edge of a braided hose. The pain of dealing with these things is worth it, especially when you need a durable high-voltage cable. Nothing can match the wear resistance of stainless steel braided hose. There are some tips you need to know when you need to cut the braided hose.

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available