Chemical Corrosion Resistant Ptfe Hose Manufacturer, Factory, Supplier In China

Besteflon, as a leading manufacturer and factory in China, specializes in producing high-performance OEM chemical corrosion resistant PTFE hoses.

Our products are renowned for their exceptional durability and reliability, and can be customized to meet specific customer requirements for various industrial applications.

Choose Besteflon to receive premium Chinese-made products and professional OEM services, ensuring safety and efficiency in your applications.

Chemical Corrosion Resistant PTFE Hose

Are you looking for the most stringent high quality chemical corrosion resistant ptfe hose?High pressure series ZXGM01 PTFE Hose can be a product that is looking for it, which is designed to withstand high equipped chemicals to provide durability and best performance even in the worst environment.

Our PTFE HOSE has enhanced fabric lining and a solid fabric lining to ensure robustness and manage the most challenging chemical metastasis in a smooth and simple way. Increases great strength.

Our multi -functional OEM chemical corrosion resistant PTFE hose is very suitable for use in various industrial environments and can maintain reliable performance within the temperature range of -65 --260° C. It ensures that it can be easily handled.

ZXGM101 Series Spec

| Item No. | Inner Diameter | Outer Diameter | Tube Wall Thickness |

Working Pressure | Burst Pressure | Minimum Bending Radius | Specification | Collar Spec. | ||||||

| (inch) | (mm) | (inch) | (mm) | (inch) | (mm) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM101-04 | 3/16" | 5 | 0.323 | 8.2 | 0.033 | 0.85 | 3770 | 260 | 15080 | 1040 | 0.787 | 20 | -3 | ZXTF0-03 |

| ZXGM101-05 | 1/4" | 6.5 | 0.394 | 10 | 0.033 | 0.85 | 3262.5 | 225 | 13050 | 900 | 1.063 | 27 | -4 | ZXTF0-04 |

| ZXGM101-06 | 5/16" | 8 | 0.461 | 11.7 | 0.033 | 0.85 | 2900 | 200 | 11600 | 800 | 1.063 | 27 | -5 | ZXTF0-05 |

| ZXGM101-07 | 3/8" | 10 | 0.524 | 13.3 | 0.033 | 0.85 | 2610 | 180 | 10440 | 720 | 1.299 | 33 | -6 | ZXTF0-06 |

| ZXGM101-08 | 13/32" | 10.3 | 0.535 | 13.6 | 0.033 | 0.85 | 2537.5 | 175 | 10150 | 700 | 1.811 | 46 | -6 | ZXTF0-06 |

| ZXGM101-10 | 1/2" | 13 | 0.681 | 17.3 | 0.039 | 1 | 2102.5 | 145 | 8410 | 580 | 2.598 | 66 | -8 | ZXTF0-08 |

| ZXGM101-12 | 5/8" | 16 | 0.799 | 20.3 | 0.039 | 1 | 1595 | 110 | 6380 | 440 | 5.906 | 150 | -10 | ZXTF0-10 |

| ZXGM101-14 | 3/4" | 19 | 0.921 | 23.4 | 0.047 | 1.2 | 1305 | 90 | 5220 | 360 | 8.898 | 226 | -12 | ZXTF0-12 |

| ZXGM101-16 | 7/8" | 22.2 | 1.043 | 26.5 | 0.047 | 1.2 | 1087.5 | 75 | 4350 | 300 | 9.646 | 245 | -14 | ZXTF0-14 |

| ZXGM101-18 | 1" | 25.4 | 1.161 | 29.5 | 0.059 | 1.5 | 942.5 | 65 | 3770 | 260 | 11.811 | 300 | -16 | ZXTF0-16 |

* Meet SAE 100R14 standard.

* Custom-specifications may be discussed with us for detailed.

Product Customization Series

Not only High pressure hose,we also have other series, such as Medium pressure hose, Medium pressure gas hose,High pressure gas hose,Light weight hose,High performance hose,Convoluted hose and so on.

We can customize the required products for customers, such as the size of customized hose, fitting, logo, packaging methods, etc;

Customized PTFE hose with chemical corrosion resistance usually need to consider the following aspects:

According to specific application requirements, the inner diameter (ID), outer diameter (OD), and length of the pipeline can be customized.

The length and size of the hose can be adjusted according to the design requirements and installation space of the system.

Customized PTFE hose typically require the selection of appropriate fitting types, such as flanges, threaded joints, etc., To ensure compatibility with existing systems or equipment connections.

Fitting materials usually need to consider their corrosion resistance and mechanical strength, and common choices include stainless steel, aluminum alloy, etc.

If it is necessary to print the company logo, model or other information on the pipeline, customized printing can be carried out.

Chemical resistant ink or labels are usually used to ensure that the identification does not affect the performance or durability of the pipeline.

When selecting and customizing these parameters, it is recommended to collaborate with professional PTFE pipe manufacturers or suppliers who can provide customized solutions based on specific needs and ensure that the quality, performance, and safety of the hose meet the requirements.

We can package according to customer requirements, such as single hose in single bag packaging, multiple tube in single bag packaging, cardboard packaging, separate packaging of tubes and fitting, assembly tube packaging and so on.

Advantageous Features of Corrosion-Resistant Ptfe Tubing

PTFE HOSE is a high-performance pipeline material, which is mainly made of polytrafluoroethylene (PTFE). It has the following main characteristics and advantages:

Strong corrosion resistance: PTFE has excellent chemical stability and can tolerate a variety of corrosive medias, including strong acids, strong alkali and various organic solvents.

Excellent pressure resistance: PTFE pipelines can withstand high pressure environments and are suitable for strict industrial applications.

Non -adhesive: The surface of the PTFE has good non -adhesive, which can effectively prevent the medium from attached to the inner wall of the pipeline, reducing pipeline cleaning and maintenance costs.

Excellent electrical insulation performance: Due to its excellent electrical insulation performance, the PTFE pipeline is widely used in electrical and electronic devices.

Long life and stability: PTFE materials have excellent aging resistance, long service life, and high stability.

Flexibility and easy installation: PTFE pipelines can bend and installed as needed, suitable for complex pipeline layout and design.

Generally speaking, PTFE pipelines are widely used in high -demand pipeline transmission systems in chemical, medicine, food processing, aerospace and other fields due to their excellent corrosion resistance, extensive temperature and excellent long life span.

Don’t you find what you are looking for?

Just tell us your detailed requirements. The best offer will be provided.

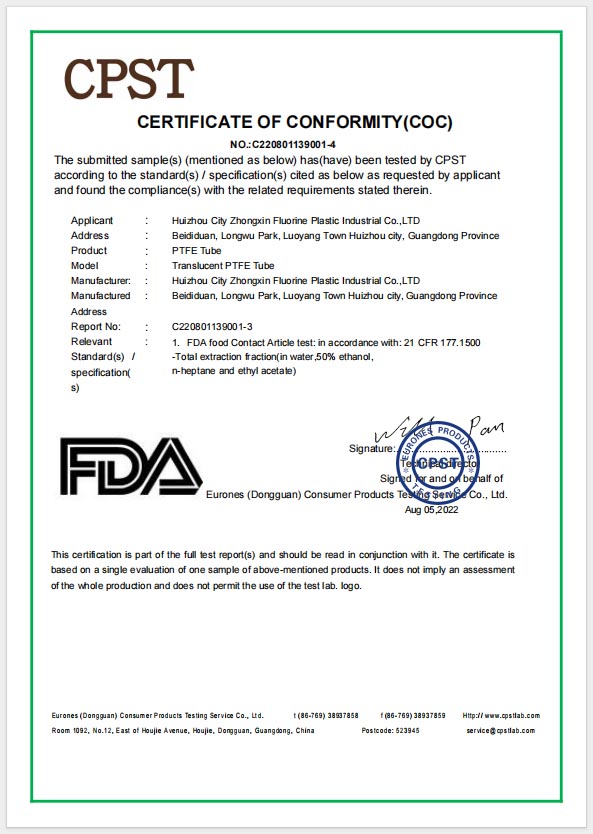

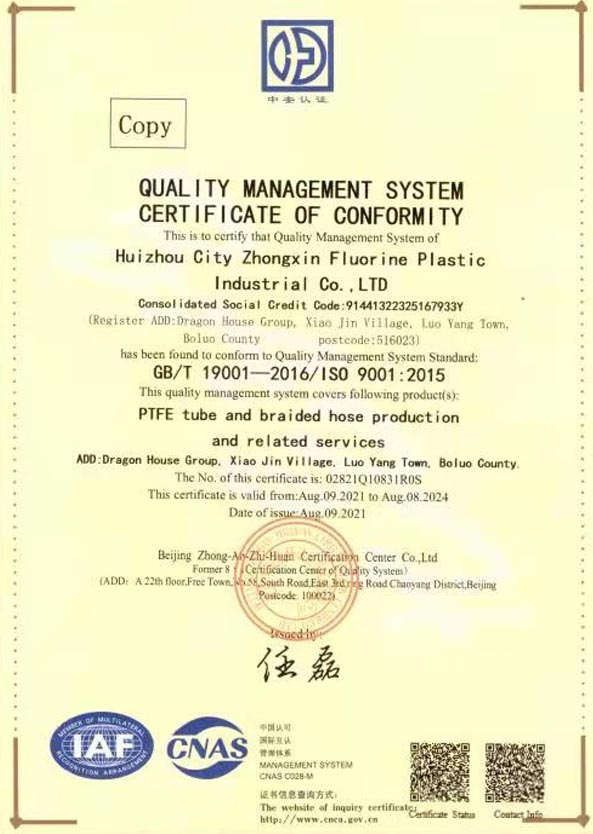

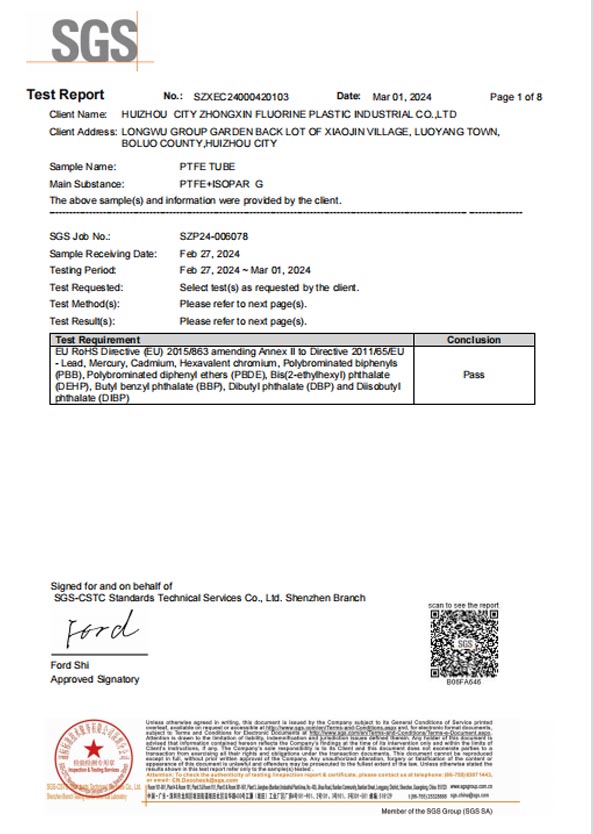

Authentication Certificate

FDA

IATF16949

ISO

SGS

FAQ

When choosing and using chemically corrosion-resistant PTFE (polytetrafluoroethylene) hose, the following are some common questions and their answers:

Industries such as chemical processing, oil and gas, pharmaceuticals, food and beverage, marine and water treatment are particularly susceptible to chemical corrosion due to the corrosive environments and chemicals they handle.

PTFE, certain grades of stainless steel (such as 316L), titanium, and various plastics and elastomers are known for their chemical corrosion resistance. The choice depends on the specific chemical substances and environmental conditions involved.

PTFE hoses can resist a wide range of chemicals, including acids, bases, solvents, and other corrosive substances. However, compatibility should always be checked against specific chemicals to ensure suitability.

- Excellent chemical resistance

- High temperature resistance

- Low friction coefficient

- Non-stick properties

- Flexibility and durability

Yes, certain grades of PTFE are FDA-approved for food contact and are suitable for pharmaceutical and biotech applications where cleanliness and non-contamination are critical.

PTFE hoses are preferred for handling corrosive chemicals due to their inert nature. They do not react with most chemicals, ensuring that the integrity of the hose is maintained and preventing contamination of the fluid being transported.

By understanding and answering these common questions, users can better understand and correctly use chemically corrosion-resistant PTFE hose, ensuring their safety and efficiency in various industrial and laboratory applications.