PTFE Brake Hose OEM Manufacturer & Supplier - China Factory

With approximately 20 years of experience since 2005, we are one of the leading manufacturer of PTFE brake hoses in China. Our advanced technology and dedicated professional team ensure top-quality products that meet stringent industry standards. Trust us for reliable, high-performance polytetrafluoroethylene brake hoses designed to deliver exceptional durability and efficiency.

Accepting OEM, ODM orders, we have rich experiences in production and research development for different PTFE brake hose types.

PTFE Brake Hoses

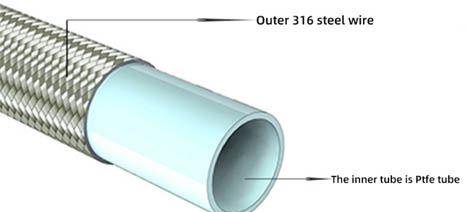

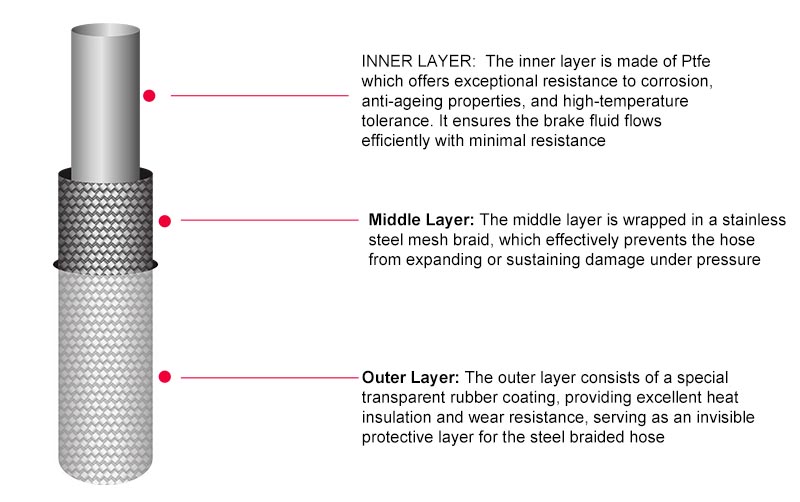

PTFE (polytetrafluoroethylene) brake tube is a high performance brake system component, which takes advantage of the unique properties of PTFE material to improve brake performance.

Properties:

Low expansion coefficient

High temperature and high pressure resistance

Compatible with almost all of the fuel

All assembly hoses have been strictly pressure-tested

Non-stick, smooth surface, low coefficient of friction

Resistance to weathering and aging performance

Applications:

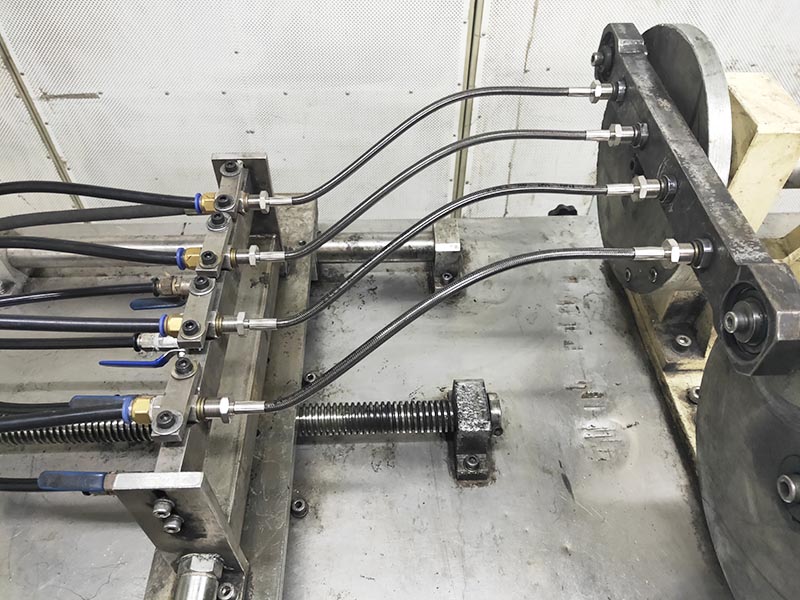

Brake system, Fuel system

Customisation Options for Ptfe Brake Hoses

As a manufacturer of PTFE brake hoses, our company offers the following customization options:

We provide hoses in a variety of lengths and diameters to meet specific requirements. Custom lengths can be tailored to fit unique applications, ensuring precise fit and optimal performance.

The inner tubes of our hoses can be designed in different selections, including smooth bore, convoluted or smooth bore convoluted tubes to suit different operational environments and spatial constraints.

We provide options for adding company logos, serial numbers, and custom markings on the hose surface, promoting brand identity and easy traceability.

We offer a wide range of end fittings and connectors, including standard and custom designs, to ensure compatibility with diverse equipment and system requirements.

| Item No. | Inner Diameter | Outer Diameter | Tube Wall Thickness |

Working Pressure | Burst Pressure | Minimum Bending Radius | Specification | ||||||

| (inch) | (mm) | (inch) | (mm) | (inch) | (mm) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | ||

| ZXAN001-03 | 9/64" | 3.56 | 0.25 | 6.35 | 0.039 | 1 | 3001.5 | 207 | 12006 | 828 | 2.008 | 51 | AN3 |

| ZXAN001-04 | 3/16" | 4.83 | 0.315 | 8 | 0.033 | 0.85 | 3001.5 | 207 | 12006 | 828 | 2.953 | 75 | AN4 |

| ZXAN001-06 | 21/64" | 8.13 | 0.430 | 10.92 | 0.028 | 0.7 | 2501.3 | 173 | 10005 | 690 | 3.622 | 92 | AN6 |

| ZXAN001-08 | 27/64" | 10.67 | 0.540 | 13.72 | 0.028 | 0.7 | 2001 | 138 | 8004 | 552 | 5.157 | 131 | AN8 |

| ZXAN001-10 | 33/64" | 12.95 | 0.630 | 16 | 0.033 | 0.85 | 1500.8 | 104 | 6003 | 414 | 7.165 | 182 | AN10 |

| ZXAN001-12 | 41/64" | 16.26 | 0.760 | 19.3 | 0.039 | 1 | 1000.5 | 69 | 4002 | 276 | 8.307 | 211 | AN12 |

| ZXAN001-16 | 7/8" | 22.22 | 1.030 | 26.16 | 0.039 | 1 | 750.4 | 52 | 3001.5 | 207 | 16.575 | 421 | AN16 |

| ZXAN001-20 | 1-1/8" | 28.57 | 1.290 | 32.77 | 0.047 | 1.2 | 627.1 | 43 | 2508.5 | 173 | 25.591 | 650 | AN20 |

*Custom-specific probucts may be discussed with us for detailed.

*Contact us for more detailed specs on other series hoses.

PTFE Brake Hoses Features/Benefits

PTFE brake hoses can operate normally under extreme temperatures, with a typical temperature range from -65°C to 260°C (-85º F to 500º F), which is crucial for the stability of vehicles during high summer temperatures or high-intensity braking.

PTFE material has excellent resistance to most chemical substances, including acids, bases, organic solvents, etc., enabling PTFE brake hoses to maintain performance in a variety of harsh environments.

The wear and impact resistance of PTFE brake hoses allow them to maintain their original precision and performance during long-term use.

PTFE brake hoses have an extremely high burst pressure, far exceeding the standards of general brake oil hoses, ensuring that the pressure inside the hose is high and stable during emergency braking or high-speed driving, preventing leaks.

The low friction coefficient of PTFE material helps to increase the flow velocity of fluids, which is particularly noticeable when compared to metal hoses.

PTFE brake hoses possess excellent aging resistance, and even with long-term outdoor use, their performance and service life are not affected by extreme temperature changes, ultraviolet radiation, or chemical corrosion.

PTFE brake hoses can withstand continuous bending, vibration, or impact, and they have better resistance to cyclic fatigue than rubber or metal hoses.

Due to the aforementioned advantages, the service life of ptfe brake hoses is typically very long, and they have an indefinite shelf life.

PTFE material is virtually impermeable to all substances, which is crucial in applications where fluid leakage prevention is necessary.

PTFE Brake Hose Manufacturing Process

Polytetrafluoroethylene (PTFE) Resin: Choose high-quality PTFE resin for its excellent chemical resistance and thermal stability.

Pre-forming: Create a pre-form of the PTFE material through a ram extruder.

Extrusion: Feed the pre-formed PTFE into an extruder to shape the hose. The extruder applies heat and pressure to form a continuous hose with the desired diameter and thickness.

Reinforcement: For added strength and durability, braid the exterior of the PTFE hose with stainless steel or other reinforcement materials.

Inspection: Conduct thorough inspections of the hose for uniformity, and dimensional accuracy.

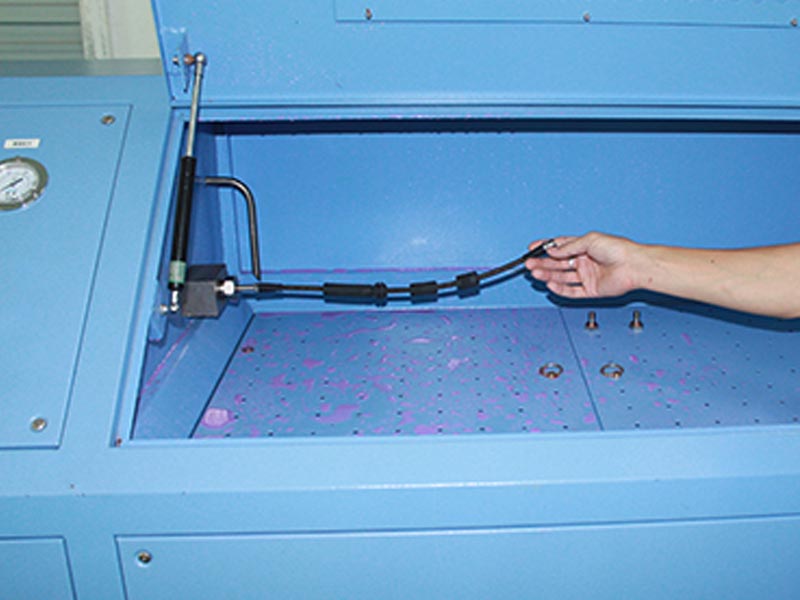

Testing: Perform pressure tests, and chemical resistance tests to ensure the hose meets industry standards and specifications.

Install a sample of ptfe assembly tubing into the test equipment, gradually increase the pressure in the tubing at a constant rate, and record the highest pressure value reached before bursting

End Fittings: Attach end fittings, such as flanges or couplings, to the hose to facilitate easy integration into systems.

Packaging: Carefully package the PTFE hose to prevent damage during transportation.

Labeling: Label the packages with necessary information, including hose specifications, batch numbers, and handling instructions.

Besteflon PTFE Brake Pipe Safety Inspection

Bending test

Bending resistance test: By applying bending force, test whether the pipeline will break, deform or leak when bent.

Dynamic bending test: Apply repeated bending loads to the brake pipe to test its fatigue strength under long-term bending

Fatigue life test

Cycling test: simulate the working conditions of the actual brake system, perform tens of thousands of brake cycles or more, test the durability and life of the brake pipe

Pulse pressure test: Apply alternating pressure (pulse pressure) for a period of time to simulate the frequent use of the braking system to test the fatigue life of the pipe.

Pressure Test

Pressure Resistance Test: Connect the brake pipe to the test device and test its ability to withstand the specified pressure (usually 3-4 times the working pressure) by applying a high-pressure fluid (e.g. brake fluid or water) to check for leakage and bursting.

Burst pressure test: Gradually increase the internal pressure until the pipe ruptures to test its maximum pressure-bearing capacity.

Sealing performance test

Connector sealing: testing the sealing performance of pipes and joints to ensure that there is no leakage under high pressure.

Tensile strength test:

Evaluate the load-bearing capacity of brake pipes under tensile loads to ensure that they can withstand external forces without breaking or deforming in actual use

Don’t you find what you are looking for?

Just tell us your detailed requirements. The best offer will be provided.

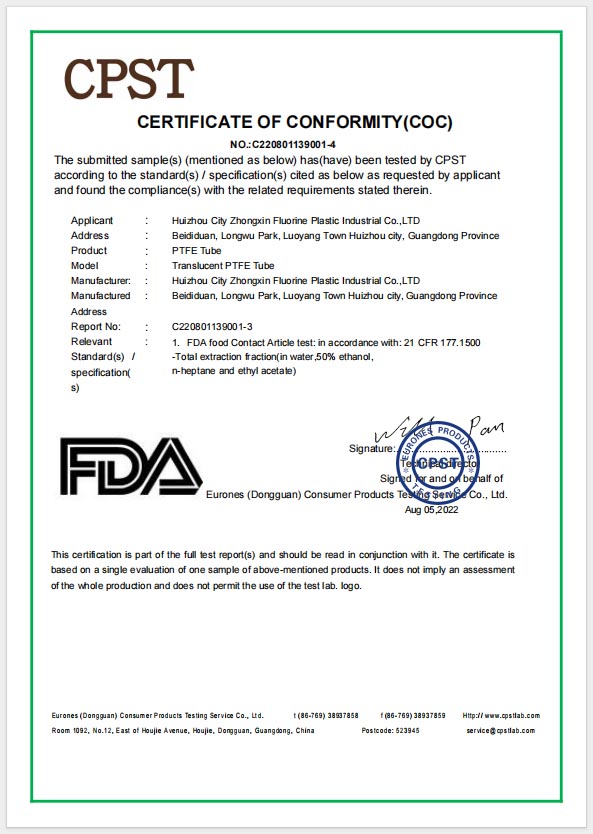

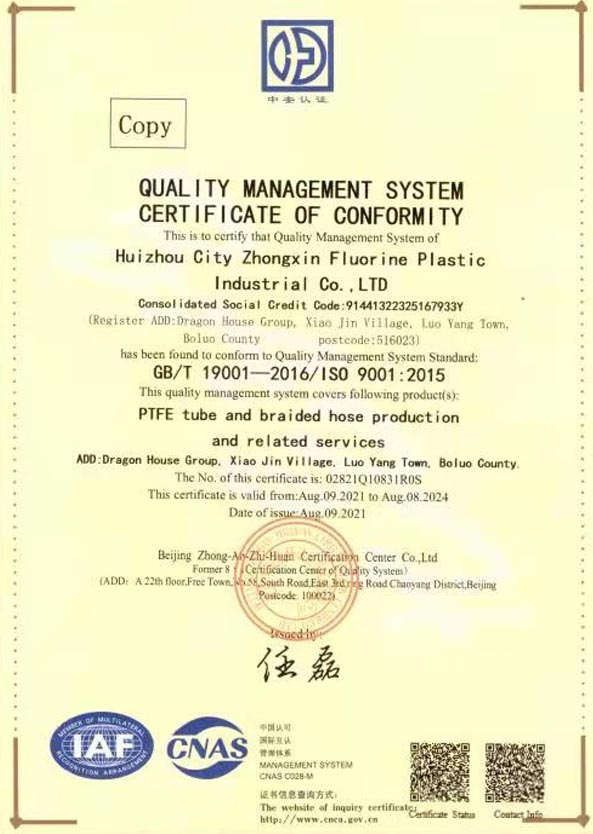

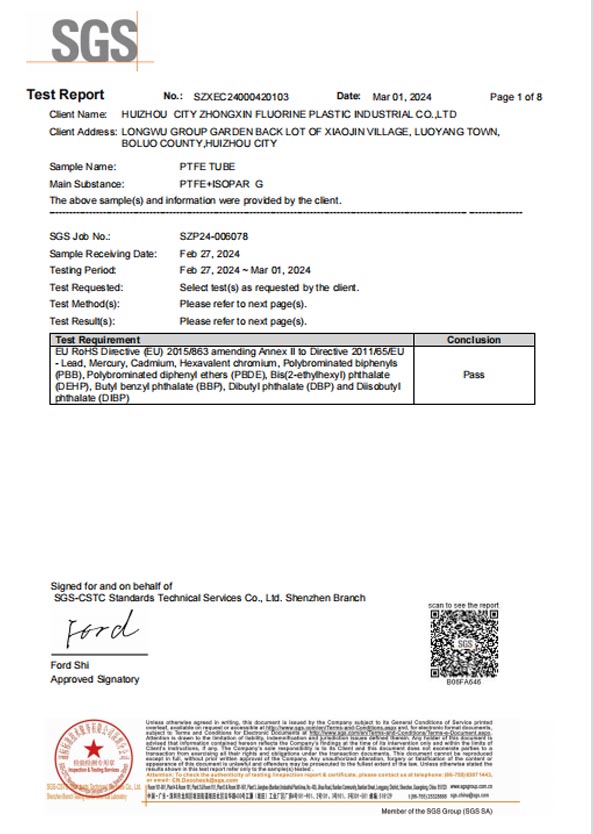

Authentication Certificate

FDA

IATF16949

ISO

SGS

FAQ

1.What are the advantages of PTFE brake hoses?

Answer: PTFE brake hoses possess excellent resistance to high and low temperatures, corrosion, and wear, making them suitable for use in various harsh environments. They are typically lighter than traditional brake hoses, offering faster braking response and greater braking efficiency. Additionally, the low friction coefficient of PTFE material helps to improve system efficiency.

2. What is the working principle of PTFE brake hoses?

Answer: The working principle of PTFE brake hoses is based on the caliper principle, similar to traditional braking systems. When the brake pedal is pressed, the master brake cylinder injects brake fluid into the brake cylinder, pushing the brake shoes against the brake disc to achieve braking.

3. How do PTFE brake hoses compare with other braking systems?

Answer: Compared to other braking systems, PTFE brake hoses offer greater reliability, lighter weight, and higher efficiency. Their chemical resistance and high-temperature tolerance enable them to maintain stable performance even in harsh environments.4. How do I choose the right conductive PTFE hose for my application?

4. What is the service life of PTFE brake hoses?

Answer: The service life of PTFE brake hoses is usually very long because they are not easily affected by environmental factors, such as temperature changes and chemical corrosion.

5. Are PTFE brake hoses suitable for all types of vehicles?

Answer: PTFE brake hoses are suitable for a variety of vehicles, including high-performance cars, racing cars, and industrial vehicles that need to operate under extreme conditions.

6. What are the maintenance requirements for PTFE brake hoses?

Answer: Maintenance for PTFE brake hoses is relatively minimal, but regular inspection and replacement are still necessary to ensure the optimal performance and safety of the braking system.

7. Are PTFE brake hoses environmentally friendly?

Answer: PTFE material is inert and does not cause environmental pollution, making it a good choice in terms of environmental friendliness.