PTFE BRAKE LINE AN3 automobile braided Stainless Steel | BESTEFLON

PTFE Brake Line AN3 For Motorcycle Or Automobile

(1) Hose structure:

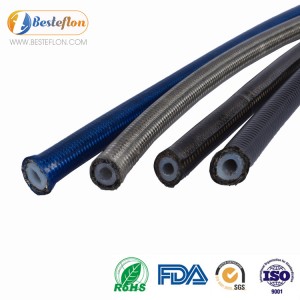

Transparent/White PTFE smooth bore tube + stainless steel 304 wire + outer colorful PVC cover (optional)

(2) Hose dimension: 3.2mm/3.5mm ID x 6.2mm/6.5mm OD after braided x 7.2mm/7.5mm OD after PVC covered, tube wall thickness is 1mm.

(3) Minimum bending radius: 12mm

(4) Working temperature: continuous temperature resistance - 65℃~+ 260℃.

(5) Max. Working pressure: 225 bar

(6) Min. Burst pressure: 900 bar

(7) Connectors details:

Material: Anodized aluminum alloy;

Thread: AN or JIC;

Types: reusable ends, crimped ends, and etc.

(8) Assembly: provide hose assembling service, can be produced according to customer’s drawings or requirements.

Product Details

| Brand Name: | BESTEFLON |

| Temperature range: | − 65 ℃~ + 260 ℃ |

| Working pressure: | 225bar ~ 44bar |

| Burst pressure: | 900bar ~ 176bar |

| Material: | 100% virgin PTFE + stainless steel 304 wire |

| Inner layer: | PTFE hose |

| Reinforcing layer: | Stainless steel 304 wire braiding |

| Outer layer: | PVC, PU (black, red, blue, yellow, green, transparent, gray, orange, etc.) |

| Available Hose size: | AN3, AN4, AN6, AN8, AN10, AN12, AN16, AN20 |

| Inner diameter | 3.2mm/3.5mm, 5mm, 8mm, 10.8mm, 13mm, 16mm, 22.2mm, 28mm |

| Outer diameter | 6.2mm/6.5mm, 8mm, 11mm, 13.7mm, 16mm, 19.3mm, 26.2mm, 32.8mm |

| Length | Random production lengths or cut pieces or customized lengths |

Product Industry Related Information

Advances of our PTFE Brake Lines:

1. PTFE liner is made of 100% virgin PTFE resin, and 100% tested by air-tightness tester.

2. Stainless steel 304 wire braided reinforced hose to increase pressure.

3. Meet SAE100 R14 and SAE J1401 specifications.

4. Test each PTFE line to 3000 psi (207 bar or 20.7Mpa).

5. Burst pressure: minimum 7250psi or 50MPa (500bar).

6. Minimal volumetric expansion (hose swelling) for powerful braking.

AN SERIES PTFE BRAKE HOSE

| No. | Specification |

Outer diameter | Inner diameter | Working pressure | Burst pressure | Minimum bending radius | |||||

| (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | ||

| 1 | -3 | 1/4 | 6.35 | 9/64 | 3.56 | 3260 | 225 | 13040 | 900 | 3/76 | 1 |

| 2 | -4 | 5/16 | 8 | 3/16 | 4.83 | 2750 | 190 | 11000 | 760 | 1/30 | 0.85 |

| 3 | -6 | 27/64 | 10.92 | 21/64 | 8.13 | 2540 | 175 | 10160 | 700 | 1/30 | 0.85 |

| 4 | -8 | 35/64 | 13.72 | 27/64 | 10.67 | 2030 | 140 | 8120 | 560 | 1/30 | 0.85 |

| 5 | -10 | 5/8 | 16 | 33/64 | 12.95 | 1740 | 120 | 6960 | 480 | 3/76 | 1 |

| 6 | -12 | 49/64 | 19.3 | 41/64 | 16.26 | 1270 | 88 | 5080 | 352 | 3/76 | 1 |

| 7 | -16 | 1-1/32 | 26.16 | 7/8 | 22.22 | 870 | 60 | 3480 | 240 | 1/21 | 1.2 |

| 8 | -20 | 1-9/32 | 32.77 | 1-1/8 | 28.57 | 630 | 44 | 2520 | 176 | 3/38 | 2 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

Learn more about BESTEFLON products

Video

Give Us A E-Mail

sales02@zx-ptfe.com

how to connect ptfe hose to tube fitting?

The range of fittings that is used with PTFE hoses is virtually unlimited in terms of the type of connection to installation.

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available