Ptfe Fuel Line Manufacturer & Supplier in China

High-Quality PTFE Fuel Line Manufacturer | Custom & Wholesale

Besteflon is a company specializing in the production and supply of PTFE (polytetrafluoroethylene) fuel hose. It is famous for its high-quality products and customized services.

As a leader in the industry, Besteflon focuses on the R&D, production and sales of PTFE hoses and related products, serving many fields such as automobile, aviation and Industry.

Common Specifications for PTFE Fuel Line

An6 (3/8"inner diameter): suitable for general automotive performance improvement and modification applications.

8an PTFE fuel line(1/2"inside diameter): suitable for high flow fuel systems and racing applications.

An10 (5/8"inner diameter): suitable for high flow and high pressure applications, such as high-performance racing cars or heavy machinery.

| Hose Type |

PTFE fuel line Stainless Steel Braided Hose |

| AN Hose Size | AN6,AN8,AN10, |

| Internal Diameter | 8mm, 10.8mm,13mm |

| Internal Material (Core) | PTFE tube |

| External Material (Overbraid) | Stainless Steel - 304/316 |

| External Material (Outer) | Nylon Braid (Black,blue,silicone rubber) |

| Minimum Temperature | -70°C, -94°F |

| Maximum Temperature | 250°C, 482°F |

| Operating Pressure | 3000 PSI, 206.8 BAR |

| Burst Pressure | 10000 PSI, 689.5 BAR |

| Minimum Bend Radius (90°) | 40mm, 1.6" |

| Fluid Compatibility | Petrol,, E10, E85, Race Fuel, Methanol, Diesel, Nitrous Oxide, Engine & Hydraulic Oil, Air, CO2, Coolant, Water, Brake & Clutch Fluid (DOT) |

Don’t you find what you are looking for?

Just tell us your detailed requirements. The best offer will be provided.

The following are the common technical parameters of PTFE fuel hose

The technical parameters of PTFE fuel hose mainly involve material performance, size, pressure resistance, temperature range and other aspects.

Inner layer: polytetrafluoroethylene (PTFE), with strong chemical stability, corrosion resistance and high temperature resistance.

Outer layer: usually reinforced with stainless steel wire braid (or Kevlar Fiber Braid), providing high strength and compressive resistance. The outer layer may also have PVC or other protective layers to prevent external wear and contamination.

Operating temperature: the operating temperature of PTFE fuel hose is usually between -65° Cand 260 ° C. Some types of PTFE hoses can be used at higher temperatures (up to 300° C), but the appropriate type needs to be selected according to the specific application scenario.

Short time temperature resistance: some PTFE fuel hoses can withstand temperatures up to 260 ° C in a short time.

Working pressure: the working pressure is usually between 1500 psi (about 103 bar) and 3000 psi (about 207 bar), depending on the diameter of the PTFE fuel hose and the outer reinforcement material. Some models can withstand higher pressures and are suitable for high-pressure fuel delivery systems.

Burst pressure: the burst pressure of PTFE fuel hose is usually much higher than the working pressure, which is usually more than 3 times of the working pressure.

Inner diameter: the inner diameter ptfe fuel line hose usually ranges from 3 mm to 25 mm. The common inner diameters are 5 mm, 6 mm, 8 mm, 10 mm, 12 mm, 16 mm and 19 mm.

Outer diameter: the outer diameter depends on the wall thickness of the inner PTFE hose and the use of the outer woven material. Common outside diameters range from 10 mm to 30 mm.

For example, common PTFE fuel hoses of 6 an PTFE fuel line, An8, An10 and other specifications have inner diameters corresponding to 3/8 inch, 1/2 inch and 5/8 inch respectively.

PTFE fuel hose has strong corrosion resistance to almost all common fuels, chemicals, solvents, greases and gases. It is not affected by acid, alkali, oil, gas, alcohol, etc., and is widely used in automotive, aerospace, chemical industry and other fields.

The minimum bending radius of PTFE fuel hose is usually between 3 times the inner diameter and 5 times the inner diameter. For example, PTFE fuel hose with 6 mm inner diameter has a minimum bending radius of 18 mm to 30 mm. For larger diameter hoses, the bending radius needs to be larger.

PTFE material has very low friction coefficient, which makes it have low wear in the transmission of high velocity fluid. The outer braided reinforcement structure of PTFE fuel hose (such as stainless steel braid or Kevlar Braid) improves its wear resistance and can adapt to the worse working environment in vehicles or machines.

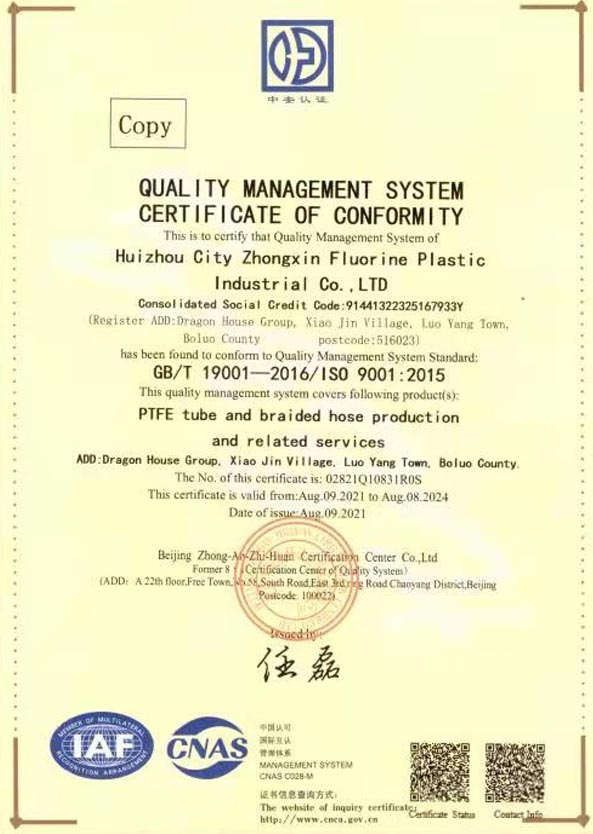

ISO 9001 certification: ensure the quality control and product consistency in the production process.

SAE J1401:Some PTFE fuel hoses meet this standard and are suitable for the delivery system of gasoline, diesel and other fuels.

UV protection: some PTFE fuel hoses adopt special coatings to prevent hose aging caused by UV radiation.

Anti static function: in some high-performance systems, PTFE fuel hoses can have anti-static function to prevent potential hazards caused by electrostatic accumulation.

Automotive and racing applications: it is suitable for fuel hoses of racing cars and high-performance vehicles because of its excellent compression resistance and high temperature resistance.

For aircraft fuel system, it can withstand extremely high temperature and pressure.

Industrial chemical transportation: widely used in chemical, pharmaceutical, food and other industries, it can safely transport all kinds of chemical substances and corrosive fluids.

Benefits of Ptfe Fuel Lines

Chemical Resistance:

PTFE is highly resistant to a wide range of chemicals, including fuels, oils, and solvents. This makes PTFE fuel lines an excellent choice for environments where exposure to corrosive substances is common.

High-Temperature Stability:

PTFE can withstand extreme temperatures (up to 260°C or 500°F), which makes it suitable for use in high-performance engines or systems exposed to heat.

Non-stick Surface:

The non-stick properties of PTFE prevent buildup of debris and fuel varnish, ensuring smooth fuel flow and longevity of the lines.

Durability and Strength:

PTFE lines are reinforced with braided stainless steel or other materials to enhance their strength and durability, ensuring they can handle high-pressure applications without failure.

Flexibility:

PTFE fuel lines are flexible and can be easily routed through tight spaces, making installation easier compared to rigid fuel lines.

Safety:

Because PTFE is non-reactive and does not degrade easily under harsh conditions, it reduces the risk of fuel contamination and leaks, making it a safer option for high-pressure fuel systems.

However, PTFE fuel lines can be more expensive than traditional rubber or other types of fuel lines. They're commonly used in high-performance or racing vehicles, aviation applications, and other demanding environments.

Why choose Besteflon as your PTFE fuel line supplier?

Expertise in PTFE Technology:

With years of experience, Besteflon is a trusted leader in PTFE manufacturing, specializing in high-performance fuel lines.

Customization:

Besteflon offers flexible custom solutions, ensuring that the products meet precise technical requirements.

Competitive Pricing:

Whether buying wholesale or in bulk, Besteflon ensures that you get top-quality products at a competitive price.

Global Reach:

Besteflon has a strong international presence, exporting their products worldwide, ensuring timely delivery and customer support.

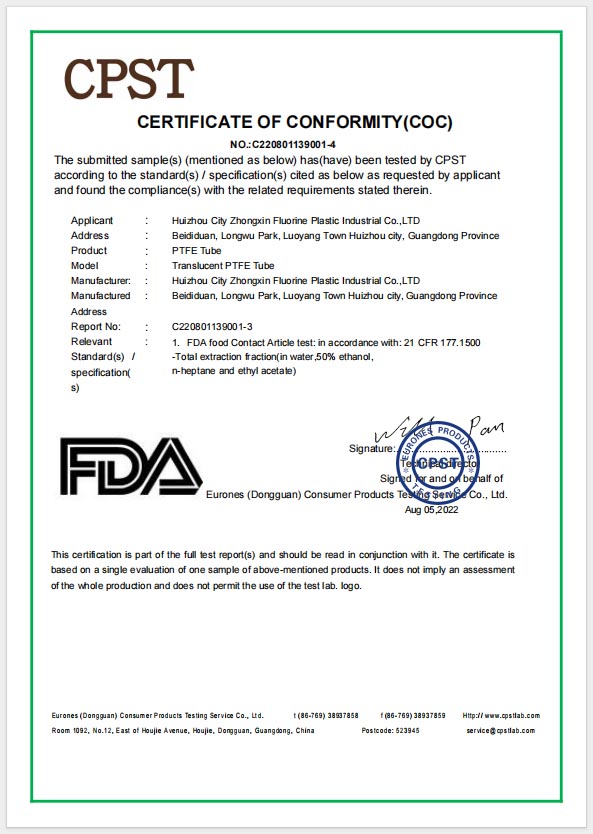

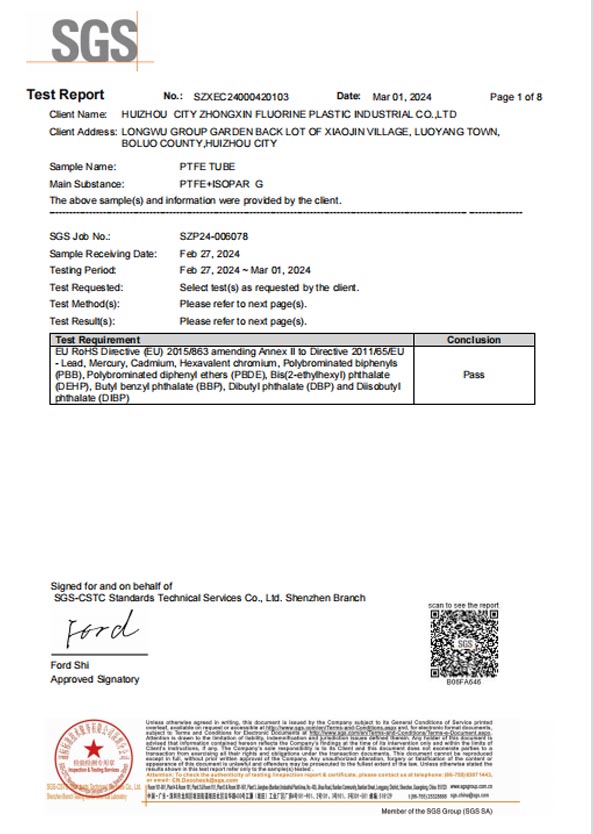

Authentication Certificate

Besteflon is a professional and formalized company. In the course of the company's development, we have continuously accumulated experience and improved our technical level, and are committed to providing customers with the highest quality products and services.

FDA

IATF16949

ISO

SGS

FAQ About PTFE Fuel Line

PTFE (Polytetrafluoroethylene) fuel lines are commonly used in various high-performance applications due to their durability, chemical resistance, and temperature stability. PTFE is a fluoropolymer known for its non-stick properties and resistance to corrosion, making it ideal for transporting fuels, oils, and other chemicals in automotive, aviation, and industrial settings.

What material is used for PTFE fuel line?

PTFE fuel lines are made from Polytetrafluoroethylene (PTFE), a high-performance fluoropolymer known for its exceptional chemical resistance, thermal stability, and non-stick properties. To enhance durability and performance, the PTFE core is often reinforced with a stainless steel or nylon braided outer layer. This construction provides superior resistance to high pressure, extreme temperatures, and compatibility with a wide range of fuels, including gasoline, diesel, E85, and biofuels.

Inner is Polytetrafluoroethylene (PTFE)

Outer is stainless steel braid/PU /PVC/Silicone/Glass Fiber/Nylon/EPDM/Polyester/Aramid Fiber

What is the temperature of hose?

Temperature range: The temperature range is:- 65 ° C to 260 ° C

What type of fuel does tube apply to?

Such as gasoline, diesel, ethanol, strong acid and alkali, etc.)

What connector type does hose usually use?

Can be connected with an connector, JIC connector, or other customized connectors

What international standards does it conform to?

Has passed SAE j1401, ISO 9001, ROHS,US FDA,EUGHS SDS)