Stainless Braided PTFE Brake, Clutch & Power Steering Hose | BESPTFE

Chief Characteristics of PTFE Hose

PTFE hoses have numerous applications and they are characterized with the following points:

1. Corrosion resistant

2. Heat and cold resistant

3. Non-toxic

4. Lightweight

5. Have low permeability

6. Can be easily cleaned

7. Fatigue resistant

8. UV or ozone resistant

Specifications of AN3 PTFE Brake Hose

Inner layer material: 100% virgin PTFE resin

Outer layer material: stainless steel 304 wire

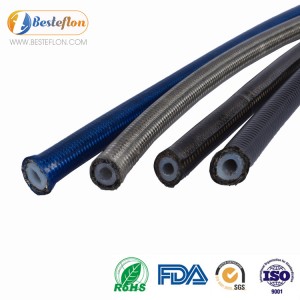

Optional version: PVC/PU cover, good protect to stainless steel layer

Inner diameter: 3,17mm

Outer diameter: 6,35mm

Maximum pressure: 207bar

Minimum burst pressure: 900bar

Minimum bending radius: 25mm

May be used only with fittings designed for PTFE hoses

Coated/Cover ptfe hose

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM112-04 | 3/16" | 4.8 | 0.358 | 9.1 | 0.033 | 0.85 | 2936 | 203 | 11745 | 810 | 2.953 | 75 | -3 | ZXTF0-03 |

| ZXGM112-05 | 1/4" | 6.4 | 0.409 | 10.4 | 0.033 | 0.85 | 2646 | 183 | 10585 | 730 | 3.189 | 81 | -4 | ZXTF0-04 |

| ZXGM112-06 | 5/16" | 8.0 | 0.512 | 13.0 | 0.033 | 0.85 | 2429 | 168 | 9715 | 670 | 3.622 | 92 | -5 | ZXTF0-05 |

| ZXGM112-08 | 3/8" | 10.0 | 0.591 | 15.0 | 0.033 | 0.85 | 1958 | 135 | 7830 | 540 | 4.331 | 110 | -6 | ZXTF0-06 |

| ZXGM112-10 | 1/2" | 13.0 | 0.701 | 17.8 | 0.039 | 1.00 | 2272 | 113 | 6818 | 450 | 7.165 | 182 | -8 | ZXTF0-08 |

| ZXGM112-12 | 5/8" | 16.0 | 0.854 | 21.7 | 0.039 | 1.00 | 1233 | 85 | 4930 | 340 | 8.307 | 211 | -10 | ZXTF0-10 |

| ZXGM112-14 | 3/4" | 19.0 | 0.969 | 24.6 | 0.039 | 1.00 | 1015 | 73 | 4205 | 290 | 338 | -12 | ZXTF0-12 | |

| ZXGM112-16 | 7/8" | 22.2 | 1.091 | 27.7 | 0.039 | 1.00 | 870 | 60 | 3480 | 240 | 421 | -14 | ZXTF0-14 | |

| ZXGM112-18 | 1" | 25.0 | 1.220 | 31.0 | 0.039 | 1.50 | 798 | 55 | 3190 | 220 | 539 | -16 | ZXTF0-16 | |

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXBW203-04 | 3/16" | 5.0 | 0.343 | 8.7 | 0.035 | 0.90 | 2944 | 203 | 8831 | 609 | 0.709 | 18 | -3 | ZX710-03 |

| ZXBW203-05 | 1/4" | 6.5 | 0.421 | 10.7 | 0.035 | 0.90 | 2489 | 172 | 7468 | 515 | 0.787 | 20 | -4 | ZX710-04 |

| ZXBW203-06 | 5/16" | 8.0 | 0.484 | 12.3 | 0.035 | 0.90 | 2001 | 138 | 6003 | 414 | 0.906 | 23 | -5 | ZX710-05 |

| ZXBW203-08 | 3/8" | 10.0 | 0.622 | 15.8 | 0.035 | 0.90 | 1730 | 119 | 5191 | 358 | 0.984 | 25 | -6 | ZX710-06 |

| ZXBW203-10 | 1/2" | 13.0 | 0.740 | 18.8 | 0.035 | 0.90 | 1498 | 103 | 4495 | 310 | 1.102 | 28 | -8 | ZX710-08 |

| ZXBW203-12 | 5/8" | 16.0 | 0.878 | 22.3 | 0.035 | 0.90 | 1160 | 80 | 3480 | 240 | 1.969 | 50 | -10 | ZX710-10 |

| ZXBW203-14 | 3/4" | 19.0 | 1.055 | 26.8 | 0.035 | 0.90 | 1015 | 70 | 3045 | 210 | 2.480 | 63 | -12 | ZX710-12 |

| ZXBW203-16 | 7/8" | 22.2 | 1.161 | 29.5 | 0.039 | 1.00 | 923 | 64 | 2770 | 191 | 3.346 | 85 | -12 | ZX710-14 |

| ZXBW203-18 | 1" | 25.0 | 1.220 | 31.0 | 0.039 | 1.00 | 793 | 55 | 2378 | 164 | 3.543 | 90 | -16 | ZX710-16 |

Production workshop

Learn more about BESTEFLON products

How would you Select The Right PTFE Brake Hose?

Here are some features that make PTFE brake hoses for different applications.

So what kind do you need?

The biggest advantage of using PTFE brake hose is its incredible flexibility. When you need a tubing to change direction, you can choose two things, either bend it or put an adapter on the elbow. This will have an impact on the flow rate and will also increase the pressure drop. The more components you add, the greater the impact on the overall cost. On the other hand, PTFE tubing has similar pressure capabilities, but may not require joints and elbows.

In jet airliners, PTFE is usually used as the main fuel pipeline. If the aircraft encounters an accident, the fuel pipe will not rupture under pressure, nor will it ultimately cause a fire hazard. The flexibility of the hose means you can easily handle the offset between any two elements in the system. For designers and installers of fluid systems, hoses are very important.

PTFE is a very hard material. Usually corrosion resistant and easy to clean. If used properly, its shelf life can be as long as several decades. It is not as easy to conduct heat as stainless steel tubes, so it provides strength and reliability for an extra dose.

Braided stainless steel hoses are much more expensive than rubber hoses. You will find that braided stainless steel brake wires can only be seen on high-end cars, such as super sports cars, or vehicles prepared for racing. Braided stainless steel brake cable is a post-purchase upgrade. This is usually purchased and installed after purchase, not before it.

Brakes: cunifer pipes or ss ptfe hoses?

Upgrade fuel line to ptfe?

How To Connect Ptfe Hose To Tube Fitting?

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available