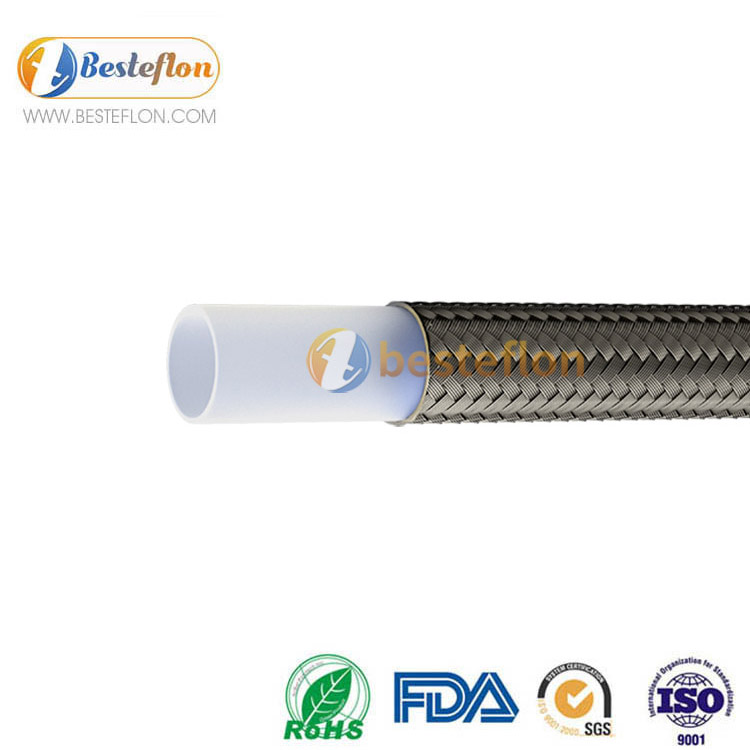

Renewable Design for Smoothbore Ptfe Hose – PTFE Smooth Bore Hose Stainless Steel Braided Hose Hydraulic Hose Industrial Hose | BESTEFLON – Besteflon

Renewable Design for Smoothbore Ptfe Hose – PTFE Smooth Bore Hose Stainless Steel Braided Hose Hydraulic Hose Industrial Hose | BESTEFLON – Besteflon Detail:

PTFE Smooth Bore Hose is flexible plastic hose with excellent performance. It is one of the best polymer materials with known stability, acid and alkali resistance and solvent resistance, high temperature resistance and UV resistance. Known as the “plastic king”. The following are the main characteristics of PTFE hoses:

1. High temperature resistance: the working temperature can reach 260℃.

2. Low temperature resistance: good mechanical toughness; even if the temperature drops to, 65℃.

3. Corrosion resistance: to be inert to most chemicals and solvents, and can withstand strong acids and strong alkali, water and various organic solvents.

4. Climate resistance: It has the best aging life in plastics.

5. High lubrication: it is the lowest friction coefficient in a solid material.

6. Non-adhesion: This is the minimum surface tension in a solid material and does not adhere to any material.

7. Non-toxic: it is physiologically inert, and does not produce adverse reactions resulting from long-term implantation as artificial blood vessels and organs.

It is because of the above outstanding performance that it is used in a variety of industries:

Chemical industry:

Almost all chemicals are highly corrosive, so PTFE hoses are the ideal choice in the chemical industry.

Medical industry:

PTFE hose has a very low friction coefficient, it means that its surface is very smooth, easy to clean, and does not cover up the bacteria or help them grow. Among them, inner tubes can be used for intubation, catheter, pipettes, and endoscopy.

Aerospace:

PTFE tubes are non-flammable fluoropolymers that have low friction factors, allowing them to work properly at extreme temperatures and pressure, which is why these tubes are used by the aircraft industry to wrap around wires and cables.

Automotive industry:

In automotive engines, fuel evaporation and fuel rail are high quality tubes made of polytetrafluoride.The brake hoses on the market are hose assembly with joints.According to its different car brake form, it is divided into hydraulic brake hose, air pressure brake hose and vacuum brake hose.Its high temperature resistance and high temperature resistance, high pressure resistance, wear resistance, corrosion prevention characteristics, make it have a long service life, without frequent replacement.

Electrical industry:

PTFE tubes have excellent electrical characteristics.They have high dielectric constant and low loss factor properties in a very wide frequency range.Therefore, PTFE tubes are used as high quality high-temperature insulation for wires and cables as well as electric heating elements and temperature sensors.

Textile industry:

Moving chemicals in pipelines used in the textile industry causes corrosion. Transfer of chemicals in pipelines used in the textile industry causes corrosion. Therefore, to avoid this problem, PTFE hoses were used and PTFE coated on the textile roller.

If you need to find the above industry or need related performance hose, please contact our sales personnel. We will give you professional reply and advice to solve your questions.

Markets:

Features/Benefits:

Applications:

Certifications:

Markets:

Hydraulic

Industrial

Fluid Transferring

Automotive

Features/Benefits:

Strong and durable

With good performance under high pressure

Extremely high temperature resistant

Resistant to almost all common chemicals

Additional fire safety

Additional fire safety

Applications:

Chemical transfer

Hot Melt

R. I.M. Reaction injection molding machines

Adiabatic air humidification system

Pumps

Steam

Textiles

Pulp & Paper

Aerospace industry

Compressed Gas

Trucks

Machinery

Turbines

Certifications:

ISO 9001

SGS

MSDS

Different material certifications

Smooth Bore Hose Range

| No. | Inner diameter | Outer diameter | Tube Wall Thickness |

Working pressure | Burst pressure | Minimum bending radius | Specification | sleeve size | ||||||

| (inch) | (mm±0.2) | (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | |||

| ZXGM111-03 | 1/8″ | 3.5 | 0.220 | 5.6 | 0.039 | 1.00 | 3582 | 247 | 14326 | 988 | 2.008 | 51 | -2 | ZXTF0-02 |

| ZXGM111-04 | 3/16″ | 4.8 | 0.315 | 8.0 | 0.033 | 0.85 | 2936 | 203 | 11745 | 810 | 2.953 | 75 | -3 | ZXTF0-03 |

| ZXGM111-05 | 1/4″ | 6.4 | 0.362 | 9.2 | 0.033 | 0.85 | 2646 | 183 | 10585 | 730 | 3.189 | 81 | -4 | ZXTF0-04 |

| ZXGM111-06 | 5/16″ | 8.0 | 0.433 | 11.0 | 0.033 | 0.85 | 2429 | 168 | 9715 | 670 | 3.622 | 92 | -5 | ZXTF0-05 |

| ZXGM111-07 | 3/8″ | 9.5 | 0.512 | 13.0 | 0.033 | 0.85 | 1958 | 135 | 7830 | 540 | 4.331 | 110 | -6 | ZXTF0-06 |

| ZXGM111-08 | 13/32″ | 10.3 | 0.531 | 13.5 | 0.033 | 0.85 | 1894 | 128 | 7395 | 510 | 5.157 | 131 | -7 | ZXTF0-06 |

| ZXGM111-10 | 1/2″ | 12.7 | 0.630 | 16.0 | 0.039 | 1.00 | 2272 | 113 | 6818 | 450 | 7.165 | 182 | -8 | ZXTF0-08 |

| ZXGM111-12 | 5/8″ | 16.0 | 0.756 | 19.2 | 0.039 | 1.00 | 1233 | 85 | 4930 | 340 | 8.307 | 211 | -10 | ZXTF0-10 |

| ZXGM111-14 | 3/4″ | 19.0 | 0.902 | 22.9 | 0.039 | 1.00 | 1051 | 73 | 4205 | 290 | 13.307 | 338 | -12 | ZXTF0-12 |

| ZXGM111-16 | 7/8″ | 22.2 | 1.031 | 26.2 | 0.039 | 1.00 | 870 | 60 | 3480 | 240 | 16.575 | 421 | -14 | ZXTF0-14 |

| ZXGM111-18 | 1″ | 25.0 | 1.161 | 29.5 | 0.059 | 1.50 | 798 | 55 | 3190 | 220 | 21.220 | 539 | -16 | ZXTF0-16 |

| ZXGM111-20 | 1-1/8″ | 28.0 | 1.299 | 33.0 | 0.059 | 1.50 | 725 | 50 | 2900 | 200 | 23.622 | 600 | -18 | ZXTF0-18 |

| ZXGM111-22 | 1-1/4″ | 32.0 | 1.496 | 38.0 | 0.079 | 2.00 | 653 | 45 | 2610 | 180 | 27.559 | 700 | -20 | ZXTF0-20 |

| ZXGM111-26 | 1-1/2″ | 38.0 | 1.732 | 44.0 | 0.079 | 2.00 | 580 | 40 | 2320 | 160 | 31.496 | 800 | -24 | ZXTF0-24 |

| ZXGM111-32 | 2″ | 50.0 | 2.224 | 56.5 | 0.079 | 2.00 | 435 | 30 | 1740 | 120 | 39.961 | 1015 | -32 | ZXTF0-32 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

Advantage

PTFE inner tube has a series of excellent properties

1) Long term use of 200 ~ 260℃ high temperature, low temperature is still soft and resistant to – 100 ℃;

2) Resistant to aqua regia and all organic solvents;

3) The best weather/aging resistance of plastic;

4) High lubrication, minimum plastic friction coefficient (0.04);

5) Adhesives with minimum surface tension and solid materials without adhesion of any substance;

6) Non-toxic physical inertness;

7) Excellent electrical performance, it is an ideal choice for class C insulation materials.

Learn more about BESTEFLON products

Video

People also ask:

1.Fkm rubber vs PTFE: which is the ultimate fluorinated material

2.How Long Do Steel Braided Ptfe Hoses Last

3.What is a smooth bore PTFE hose

Product detail pictures:

Related Product Guide:

Our advancement depends over the highly developed devices, excellent talents and continually strengthened technology forces for Renewable Design for Smoothbore Ptfe Hose – PTFE Smooth Bore Hose Stainless Steel Braided Hose Hydraulic Hose Industrial Hose | BESTEFLON – Besteflon , The product will supply to all over the world, such as: Birmingham, Ecuador, Argentina, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.