Lilemong tsa morao tjena, polytetrafluoroethylene (Teflon) ke mofuta oa lihlahisoa tse thibelang litšila le tse khahlanong le litšila bakeng sa indasteri ea matla a motlakase le petrochemical.Leha ho le joalo, mathata a latelang a lokela ho lefshoa ka ho khetheha ha aPTFE e kenngoahosemohala o cheselitsoe, ho seng joalo bophelo ba ts'ebeletso le polokeho ea phaephe e kentsoeng ea PTFE e tla ameha.

1. Ha u hloekisa setsi sa kopano, ho thibetsoe ka thata ho senya tšepe ea motheo.Ho thibetsoe ho otla arc holim'a tšepe ea motheo nakong ea welding.

2. Karolong ea fillet ea fillet weld, bophahamo ba fillet weld e tla ba kholo ho feta 5mm, angle ea projeke e tla ba kholo ho feta kapa e lekanang le 3mm, 'me lehlakoreng le ka hare le tla ba le leholo ho feta kapa le lekanang le 10mm.

3. Ha tjheseletsa khetla ea PTFE lined pipe, ho molemo ho amohela mokhoa oa ho tjheseletsa oa mahlakoreng a mabeli butt welding.Sena se hloka boemo botekgeniki ba basebetsi ba rona, tjheseletsa e lokela ho ba a bataletseng (boreleli kapa boreleli phetoho), ha ho pores, tjheseletsa seam le slag kenyelletso ketsahalo, le bophahamo ba tjheseletsa lokela ho ba moholo ho feta 2mm.Ka mor'a ho cheselletsa, spatter e bakoang ke welding e tla tlosoa ka ho feletseng.

4. tjheseletsa e tsoelang pele e lokela ho amoheloa ka tjheseletsa ea PTFE lined pipe, 'me weld seam e ke ke ea ba le mapetsong kapa undercut e tsoelang pele.Lipatlisiso Tse Amanang:e lohiloeng PTFE hose, PTFE hose e koetsoeng

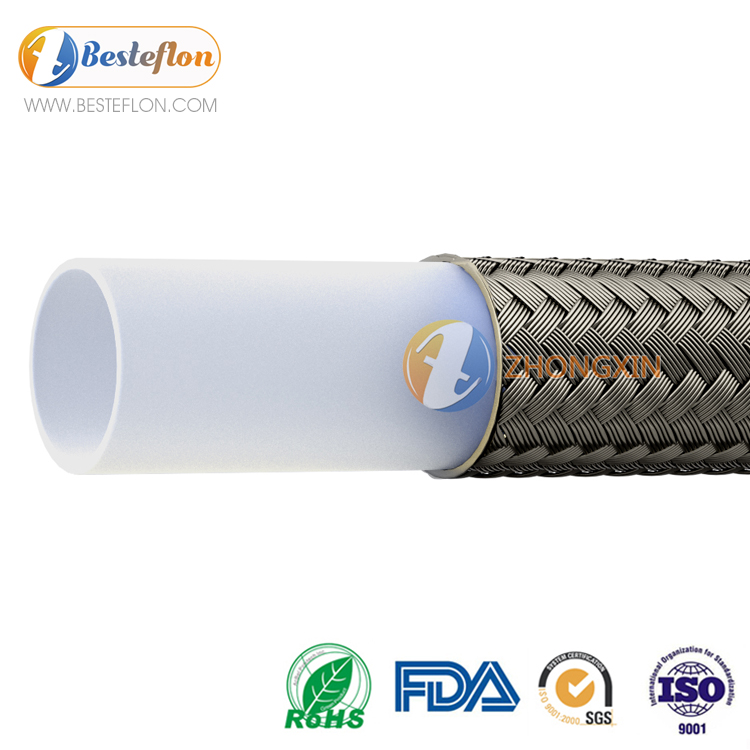

Polytetrafluoroethylene (PTFE) ke e 'ngoe ea mabitso a sebelisoang hangata a polytetrafluoroethylene.Hose ea PTFE e sebelisoa hose ea tšepe e sa hloekang, kahoo bophelo ba tšebeletso ea hose bo bolelele ho feta hose ea rabara kapa hose ea rabara e phuthetsoeng ka tšepe e sa hloekang.E na le melemo e mengata ho feta lihlahisoa tsa rabara.

Sehlopha sa I: PTFE e kentse phala e otlolohileng le lisebelisoa tsa lipeipi

Hangata e tsejoa e le loose liner pipe.Ts'ebetsong ena, PTFE e sebelisoa ho fetola bar.E loketse khatello e tloaelehileng le phaephe ea sepalangoang ea khatello e ntle (joalo ka liphaephe tse tharo tsa ho hloekisa litšila, joalo-joalo), 'me ha ea lokela ho sebelisoa bakeng sa phaephe e nang le phahlo (joalo ka ho kena le ho tsoa ha pompo le phaephe e ka hlahisang khatello e mpe. ka ho theoha kapa ho tsidifala hanghang).

Tlhaloso ea bophara: dn25-500mm

Mocheso oa tšebeletso: - 40-180oc

Khatello ea tšebeletso: 1.6Mpa

Sehlopha sa II: PTFE e kentsoeng peipi e otlolohileng le lisebelisoa tsa lipeipi

Hangata e tsejoa e le phala e thata e phuthetsoeng ka terata ea tšepe.

Mokhoa oa tlhahiso: pele, likarolo tse 'maloa tsa filimi ea PTFE li lematsoa ka hlobo, ebe terata ea tšepe (Ø 0.5-1mm) e lematsoa ka moea ka filimi ea PTFE, ebe likarolo tse' maloa tsa filimi e tšesaane ea PTFE li lematsoa ka ntle ho tšepe. terata, 'me qetellong a phuthetsoe ka sebōping bakeng sa ho theha.Lerako le ka hare la PTFE le phala e entsoeng ka mokhoa ona le boreleli, 'me lerako le ka ntle le na le spiral corrugated ka lebaka la molumo le matla a elastic a terata ea tšepe.

Sebaka pakeng tsa lerako le ka ntle la PTFE phala e kentsoeng le lerako le ka hare la phala ea tšepe le tletse resin (ntle le moea o setseng).Resin e tlatsang e ka kopanngoa ka thata ho pipe ea tšepe.Ka nako e ts'oanang, e ka phutheloa ka thata leboteng le ka ntle la spiral PTFE liner.Ka mor'a ho phekoloa ha resin e tlatsitsoeng, ho thehoa ripple ea spiral e koetsoeng ka lerako le ka ntle la lesela.Sebopeho sena se tšoana le motsoako oa linate le bolt.Ka lehlakoreng le leng, e ka fokotsa le ho lefella katoloso ea mocheso le ho fokotsa ho bata ha lesela la PTFE;ka lehlakoreng le leng, ho satalla terata ea tšepe ho ka ntlafatsa haholo khatello e mpe ea khatello ea lesela la PTFE.

Tlhaloso ea bophara: dn25-200 mm

Mocheso o sebetsang: - 50-180oc

Khatello ea ho sebetsa: 0.5-1.6mpa

Mofuta oa boraro: PTFE push (squeeze) pipe e kentsoeng ka thata ka pipe e otlolohileng

Ka tloaelo e tsejoa e le push (squeeze) lined straight pipe, e sebelisoa haholo linaheng tse tsoetseng pele lilemong tsa bo-1990.

Mokhoa oa tlhahiso: pele, phofo ea PTFE e tsoang linaheng tse ling e sebelisoa ho sutumelletsa (extrude) phala, ebe e kenngoa ka har'a pipe ea tšepe e se nang seam (bophara bo ka ntle ba liner bo nyenyane ho feta bophara bo ka hare ba phala ea tšepe ka 1.5- 2mm) ho theha lesela le thata le se nang moeli.E le ho felisa khatello, e kenngoa ka sebōping 'me e futhumetse ho 180oC bakeng sa phekolo ea kamehla ea mocheso, e le hore e ka sebelisoa mocheso o ka tlase ho 180oC.Ka nako e ts'oanang, sutumelletsa (petetsa) sefate sa phala

Matla a tsitsipano a hlakile ho feta a tube ea leqeba.Pipeline e na le khanyetso e loketseng khatellong e ntle le e mpe.

Phapang lipakeng tsa lesela la PTFE le lera la rabara

Lesela la tetrafluoroethylene le sebelisoa ho hanyetsa kutu ea fluorine, ho hanyetsa mocheso o phahameng, acid e matla le khanyetso ea alkali, ho khomarela ka mokhoa o babatsehang, bophelo bo bolelele ba tšebeletso le khanyetso e matla ea ho kenella.Tetrafluoroethylene eohle ea ho fafatsa ke mosebetsi oa theknoloji e phahameng, ts'ebetso ea eona e phalla joang?1. Pele o fafatsa, bokaholimo bo hloka ho ts'oaroa ka lehlabathe le ho hloekisoa, 'me ho fafatsoa lera la primer e khethehileng.2. Joale phofshoana ea fluoroplastic e qosoa ka lisebelisoa tse phahameng tsa motlakase oa motlakase, 'me e ts'oaroe ka mokhoa o ts'oanang holim'a sebaka sa mosebetsi tlas'a ketso ea tšimo ea motlakase.3. Ka mor'a ho baka mocheso o phahameng, likaroloana tsa clinker li tla qhibiliha ka har'a lera le letenya le sireletsang, le khomaretsoeng ka thata holim'a sebaka sa mosebetsi.Ka mohlala, filimi ea ho roala e boima ba 1 mm e boetse e hloka ho fafatsoa le ho apeha ka makhetlo a 5-6.Ka kakaretso, botenya bo boholo bo ka fafatsoa ho 2mm.PTFE linening ke theknoloji e sebelisoang haholo ha joale.E sebelisa ka botlalo ho hanyetsa kutu ea fluorine, bohloeki bo phahameng, bohloeki, ho se tsitse, ho se kolobise, ho itlotsa, ho hanyetsa, ho hanyetsa mocheso o phahameng le o tlase, ho kenya letsoho, joalo-joalo ts'ebetsong ea kaho, motlakase oa eona le hona joale li lula li fetoloa ho boemo bo loketseng ho fihlela phello ea ho roala.Lesela la rabara le boetse le bitsoa lesela la rabara.Ke ho khomarela poleiti ea rabara e entsoeng holim'a tšepe e nang le sekhomaretsi ho arola sebaka se senyang ho tloha matrix a tšepe ka morero oa ho sireletsa.Rabara ea tlhaho le rabara ea maiketsetso li sebelisoa bakeng sa lesela.Boholo ba rabara e sebelisoang ka har'a lesela la thepa ea lik'hemik'hale ke rabara ea tlhaho.Karolo e ka sehloohong ea rabara ea tlhaho ke cis polymer ea isoprene, e senyehang ka ho eketsa sebabole.Rabara e nang le vulcanized e na le ho hanyetsa mocheso o itseng le matla a mochine.E ka aroloa ka rabara e bonolo, rabara e thata-thata le rabara e thata mefuta e meraro.Rabara e thata e na le khanyetso e ntle ea kutu, e hanyetsa botsofali le matla a maqhama a matla le tšepe.Rabara e bonolo e na le ho hanyetsa serame hantle, ho hanyetsa mocheso le ho hanyetsa tšusumetso, 'me e na le elasticity e itseng;semi hard rabara e pakeng tsa tse peli.Ntle le li-oxidants tse matla le li-solvents tse ling, rabara e thata e ka hanela ho bola ha li-acid tse ngata tsa inorganic acid, organic acid, alkalis, matsoai le lino tse tahang.Ka hona, lesela le thata la rabara le sebelisoa e le thepa e ka sehloohong e se nang tšepe e thibelang kutu.Rabara e nang le vulcanized e ka aroloa ka rabara ea pre vulcanized, rabara e tloaelehileng ea metsi a chesang a chesang le rabara ea tlhaho e nang le vulcanized.Pre vulcanized rabara e sebelisoa lisebelisoa tse kholo tsa ho khetha.

Lipatlisiso tse amanang le ptfe hose:

Nako ea poso: Dec-10-2020