Stainless braided flexible ptfe brake hose | BESTEFLON

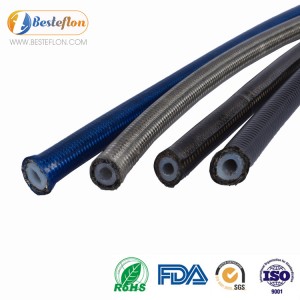

Stainless braided flexible PTFE brake hose

PTFE has supreme chemical resistance and will not break down even after years of use with methanol.

Besteflon high-quality stainless steel wire braided fuel lines can be connected with straight, 45, 90, and 180-degree hose fittings and with black aluminum alloy material at both ends.

They are suitable for brake and clutch systems as well as pressure gauges or nitrous acid. PTFE inner hose with protective stainless steel braided cover makes this line strong and flexible.PVC coating protects the steel wire layer, making the pipe more wear-resistant.

Application:

Besteflon PTFE fuel hose is designed to withstand the corrosive effects of modern fuels. making it compatible with a variety of fuels and additives. It can be used in the hydraulic brake transmission pressure systems of all automobiles. Special for motorcycles, Racing, racing, and UTV. ATV, etc.

Product Details

| Brand Name: | BESTEFLON |

| Temperature range: | − 65 ℃~ + 260 ℃ |

| Working pressure: | 225bar ~ 44bar |

| Burst pressure: | 900bar ~ 176bar |

| Material: | PTFE |

| Inner layer: | ptfe hose |

| Reinforcing layer: | stainless steel wire braiding |

| Outer layer: | PVC, PU (black, red, blue, yellow, purple, transparent, gray, orange, etc.) |

| Hose size | An3, an4, an6, an8, an10, an12, an16, an20 |

| Inner diameter | 3.56mm, 4.83mm, 8.13mm, 10.7mm, 13mm, 16.3mm, 22.2mm, 28.6mm |

| Outer diameter | 6.35mm, 8mm, 10.9mm, 13.7mm, 16mm, 19.3mm, 26.2mm, 32.8mm |

| Length | any length |

Features of stainless steel braided PTFE brake hose:

AN SERIES PTFE BRAKE HOSE

| No. | Specification |

Outer diameter | Inner diameter | Working pressure | Burst pressure | Minimum bending radius | |||||

| (inch) | (mm±0.2) | (inch) | (mm±0.1) | (psi) | (bar) | (psi) | (bar) | (inch) | (mm) | ||

| 1 | -3 | 1/4 | 6.35 | 9/64 | 3.56 | 3260 | 225 | 13040 | 900 | 3/76 | 1 |

| 2 | -4 | 5/16 | 8 | 3/16 | 4.83 | 2750 | 190 | 11000 | 760 | 1/30 | 0.85 |

| 3 | -6 | 27/64 | 10.92 | 21/64 | 8.13 | 2540 | 175 | 10160 | 700 | 1/30 | 0.85 |

| 4 | -8 | 35/64 | 13.72 | 27/64 | 10.67 | 2030 | 140 | 8120 | 560 | 1/30 | 0.85 |

| 5 | -10 | 5/8 | 16 | 33/64 | 12.95 | 1740 | 120 | 6960 | 480 | 3/76 | 1 |

| 6 | -12 | 49/64 | 19.3 | 41/64 | 16.26 | 1270 | 88 | 5080 | 352 | 3/76 | 1 |

| 7 | -16 | 1-1/32 | 26.16 | 7/8 | 22.22 | 870 | 60 | 3480 | 240 | 1/21 | 1.2 |

| 8 | -20 | 1-9/32 | 32.77 | 1-1/8 | 28.57 | 630 | 44 | 2520 | 176 | 3/38 | 2 |

* Meet SAE 100R14 standard.

* Customer-specific products may be discussed with us for detailed.

people also ask:

Give Us A E-Mail

sales02@zx-ptfe.com

Supplier's Popular Products

Question 1:How many days does it take to sample? About the delivery date of mass production?

The delivery time of samples is about 5 days, and the delivery time of mass production is determined by your order, generally about 15 days.

Question 2: What are the main materials?

PTFE / FEP / PU / stainless steel wire / cotton / copper, stainless steel, carbon steel joint

Question 3: What is the inner diameter and connection method?

Can be produced or customized according to your requirements.

Question 4:Can you provide OEM service?

We can provide OEM service. It will depend on your requirements; your logo will be customized according to our products

We offer the usual packing as follows

1、Nylon bag or poly bag

2、Carton box

3、Plastic pallet or plywood pallet

Customized Packaging is charged

1、Wooden reel

2、Wooden case

3、Other customized packaging also available